Testing diesel injectors quickly and inexpensively

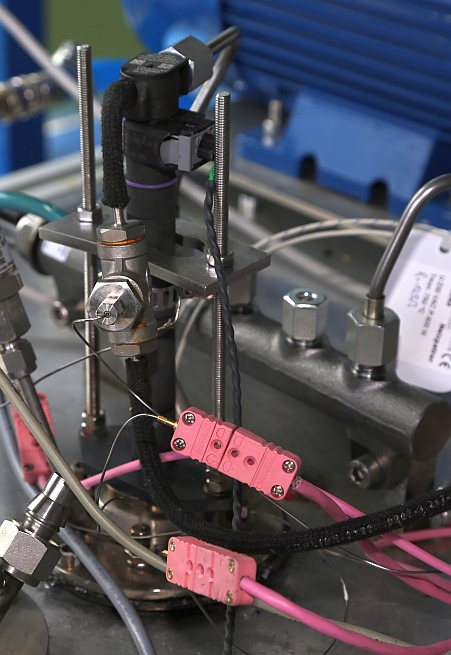

Diesel injector in the ENIAK test stand. Photo: TEC4FUELS

The injection systems of modern diesel engines are becoming increasingly powerful. The often observed Internal Diesel Injector Deposits (IDIDs) can impair their function.

The Quick Test for Diesel Injectors can precondition injectors with Internal Diesel Injector Deposits (IDID) within 200 hours, which otherwise requires up to 100,000 kilometers of field mileage. Pre-conditioned injectors can then be used by engine, injector, fuel and additive manufacturers to develop strategies such as engine management adjustments or additive selection. The following test options are possible, for example:

- Testing of different injectors or specific injector series

- Comparative tests of specified fuels, blends and additives

- Injector operation at different operating points (e.g. defined temperatures, injection pressures), some of which would not be feasible in test engines.

Advantages of the injector rapid test

- Cost-effective: Low costs compared to the DW10 due to simple test riginfrastructure and low fuel consumption due to absence of engine combustion.

- Fast: HiL test procedure enables high time savings, forced test conditions and decisive results already after 200 hours.

- Flexible: Integration of different common-rail systems and simulation under stricter conditions is possible. The test bench can be adapted to specific customer requirements and offers variable settings for test and injection conditions.

Download

Folder Fouling test for diesel fuel injectors

PDF-Dokument [2.2 MB]