Ageing-Test for middle destillates

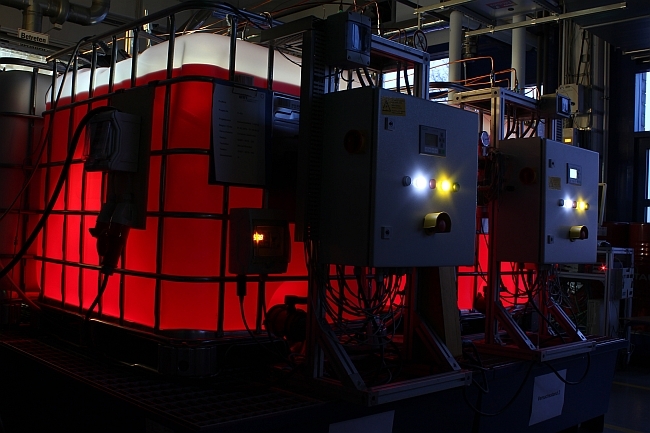

At the test bench, 4,000 litres of heating oil are forced to age in order to test the effectiveness of an anti-ageing additive. (Photo: TEC4FUELS)

The ageing test is a hardware-in-the-loop (HiL) test procedure for the targeted and forced ageing of middle distillates and blends with alternative fuels (e.g. FAME fatty acid methyl ether, HVO hydrogenated vegetable oil, BtL biomass-to-liquid) as well as middle distillate components and additives. In this process, which simulates the conditions in the boiler room, two middle distillates of different quality are pumped in a circuit and loaded with light, heat and oxygen over a defined period of time. The “ageing” fuel flows through the filter, pump, preheater and nozzle in the circuit. Standardised measurement methods, such as thermal stability (DIN 51371) or the Rancimat test (DIN 15751), are indicators for the status of ageing at defined points in time of the ageing test.

Further indicators are system-specific, such as pressures, volume flows or temperature profiles. Comparisons of the results of both middle distillates allow for differentiating statements.