Check the quality of fuel supplies annually

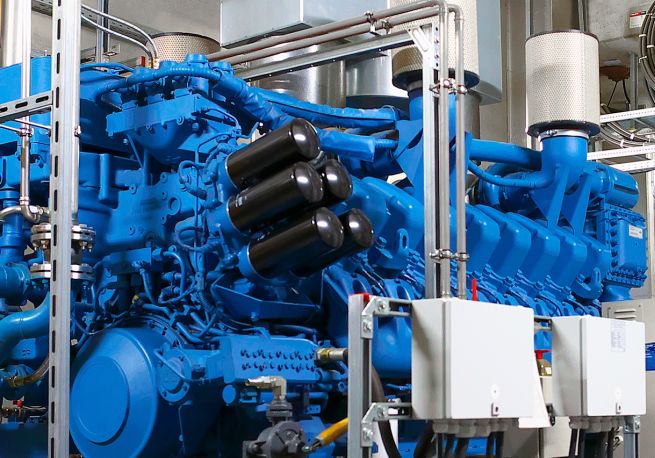

16 August 2021 – Prolonged power outages are not as rare as they seem. Berlin Köpenick in January 2019, Hamburg Airport in June 2018 and the Interxion Internet hub in April 2018 are some “prominent” examples. In such cases, emergency power systems step in to provide emergency power to the infrastructure. If the engine of an emergency generator fails after a short time, this may be due to overaged fuel that is no longer fit for use. Regular fuel checks are therefore important in order to be able to react to changes in the fuel in good time.

As a study by the Institut für Wärme und Mobilität e.V. (IWO) shows, fuel quality is hardly the focus of operators of emergency power supply systems. This is critical for two reasons: standby fuels are often stored for several years; but their chemical composition only allows a limited storage time. Fuels in grid replacement systems are never completely renewed, as their tanks should never be empty at any time. Thus, during refueling, new fuel mixes with aged stock. In the study, 60 percent of the diesel fuels containing biodiesel were unusable – or close to it. In total, this applies to 30 percent of all investigated fuels. The critical fuel quality means that reliable operational readiness of these emergency power systems is not assured today.

The installation of copper lines and the use of commercially available diesel with biodiesel content are two factors that can significantly affect the storage stability of the fuel. Copper lines are often used to supply fuel between the tank and the engine. However, the catalytic influence of non-ferrous metals leads to faster aging of the fuel with negative consequences for its suitability for use. Engine manufacturers generally require the use of diesel fuel in accordance with DIN EN 590, to which up to 7% biodiesel is now commonly added in order to comply with the Biofuel Quota Act. With its special properties, this fuel quality is designed for the transport sector with consumption within 90 days, but not for long-term storage. In the case of biogenic blends, longer storage periods for diesel stocks increase the risk of fuel-related malfunctions of the emergency power system due to degradation and microbiological contamination.

Checking the quality of the fuel supply

Following the publication of the IWO study, the German Federal Office of Civil Protection and Disaster Assistance (BBK) and the German Federal Office for Information Security (BSI) have revised their guidelines and recommended measures for planning, setting up and operating an emergency power supply in companies and public authorities to ensure the quality and operational readiness of stockpiled fuels. In order to ensure the permanent functionality of emergency power systems and to detect critical changes in fuel quality at an early stage, BBK and BSI recommend having the fuel quality tested at least once a year. The quality of the fuel in the day tank is the critical variable and should be monitored as a matter of priority.

The following recommendations on fuel and installation will help to avoid fuel-related malfunctions and functional failures of the emergency power system:

- Make all oil-carrying piping stainless steel or aluminum, as copper accelerates fuel aging.

- Use low-sulfur fuel oil according to DIN 51603-1, as this fuel must not contain any biodiesel. Leading manufacturers have already approved the use of low-sulfur fuel oil according to DIN 51603-1 for their engines on the basis of IWO studies and even recommend it explicitly.

- Condition the low-sulfur heating oil with an additive package. For the use of low-sulfur heating oil in diesel engine network replacement systems, the use of special additives is recommended to optimize the performance of the engine as well as the operational reliability and durability of the system. Among other things, the special additive’s combination of active ingredients should increase the cetane number above the minimum level required by manufacturers even in fuel oil operation, protect against corrosion and deposits, clean the fuel system and keep the injection nozzles clean. In addition, it should increase long-term storage capability through stabilizers and prevent possible bacterial growth through biocides.

TEC4FUELS GmbH supports operators in the quality management of stocked standby fuels with a comprehensive range of consulting and services. The focus is on monitoring the quality of the fuel supply through regular sampling, analysis, evaluation and recommendations for further operational safety. This is supplemented by advice on the selection and additivation of standby fuels and their replacement. This includes information on the safe use and proper storage of standby fuels.